According to the HFS Horizons: Supply Chain Services, 2023 study, supply chains face issues related to visibility, resilience, connectedness, and sustainability. The study identified Capgemini as a Horizon 3 service provider, recognizing its ability to help its clients discover new value streams by making their supply chains more networked, connected, and automated.

To further enhance its value proposition, in September 2023, Capgemini announced a strategic partnership with Kuehne+Nagel, a global leader in logistics management and freight-forwarding services. The collaboration aims to solidify both companies’ positions as supply chain orchestrators with a unique service offering integrating supply chain planning, data, procurement, and order fulfillment with logistics management capabilities.

Supply chain and logistics management have always operated separately, leading to unreliable lead-time data and inaccurate inventory data. This siloed approach often causes missed cost efficiencies due to poor capacity utilization, and in-transit inventory often goes missing.

To solve this, Capgemini’s Intelligent Supply Chain Operations function (ISCO) and Kuehne+Nagel Integrated Logistics, the 4PL division of the Kuehne+Nagel Group, are working together to integrate planning and execution, optimize logistics capacity, optimize in-market and in-distribution centers inventory, and provide reliable shipment forecasts at the lane level (as illustrated in Exhibit 1). They aim to unlock the unexplored value in supply chain areas by combining their expertise.

The partnership tackles data and process challenges, not just technical integration. For example, it could solve a consumer goods firm’s inbound supply reliability issues by combining Capgemini’s planning operations and Kuehne+Nagel’s logistics insight and technology platform. This partnership will provide a new level of supply flows and logistics visibility, which are tightly connected with Capgemini’s planning capability. The planners will have real-time, lead-time, and carrier-specific information to make informed decisions. All this information will enable the client to receive in-advance information on ETAs and critical supply inflows, thus avoiding manufacturing downtime and empty shelves.

Source: Capgemini

For the past 18 months, both firms have been working on formalizing their go-to-market approach, governance structure, service delivery responsibility, performance metrics, and annual targets.

Their go-to-market approach involves co-training both companies’ business development teams to present a consistent message. The services and solutions architecture, transition and onboarding processes, and IT and sales teams are also aligned. Joint operations require a harmonized statement of work (SOW), control towers, and processes. They approach clients with specific problem statements and use cases, emphasizing the need for collaboration and integration capabilities. Logistics control tower capabilities are part of the primary offering.

The partnership’s governance structure and service delivery responsibility are governed by a single entity that owns service delivery to the customer. There is no formal joint entity; instead, either Capgemini or Kuehne+Nagel will be the primary service provider for the engagement based on the client’s engagement nature and preferences.

Both companies have set ambitious business development targets and timelines that will be measured against market success and customer feedback, and they have formulated a mechanism to capture customer feedback regularly.

However, some elements have yet to be integrated, such as a few technologies and proprietary assets of both firms. The firms plan to do this during their first joint client implementation.

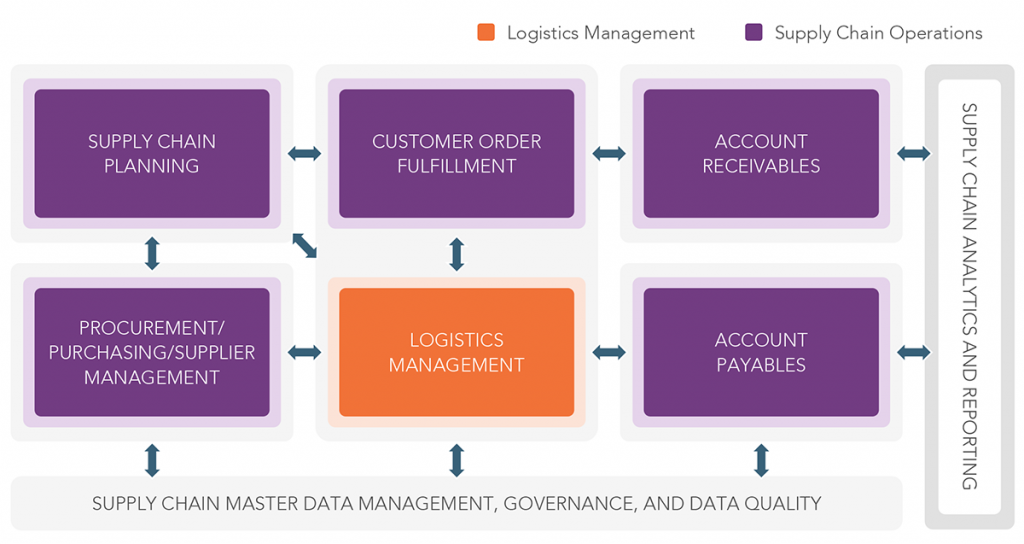

Enterprises want their supply chains to be low touch, have end-to-end visibility, optimize business processes, and manage risks. Capgemini and Kuehne+Nagel’s partnership focuses on six dedicated offerings (refer to Exhibit 2) that aim to achieve these goals, primarily targeting Fortune 500 and large corporations.

Source: Capgemini

These services also promise to reduce the carbon footprint of related activities. The target industries are consumer goods, life sciences, and manufacturing, mainly for global corporations headquartered in Europe and North America.

The services mentioned above are powerful but not unique. Most of Capgemini’s competitors offer similar services. However, the deep integration with Kuehne+Nagel gives Capgemini the advantages of faster implementation times and achieving above-par quantified outcomes across the value chain, including sourcing, distribution, planning, and fulfillment.

The capabilities of both companies complement each other and prioritize easy sharing of supply chain master data among different functions. Supply chain decision makers will immediately realize the potential value that can be unlocked from this combined entity, which enables the orchestration of complex and often isolated supply functions within an enterprise.

Register now for immediate access of HFS' research, data and forward looking trends.

Get StartedIf you don't have an account, Register here |

Register now for immediate access of HFS' research, data and forward looking trends.

Get Started